Thermogravimetric Analysis (TGA) for Precise Material Insights

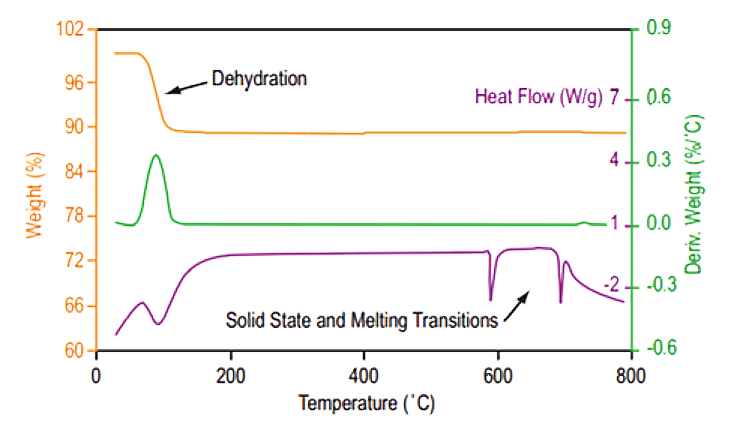

Thermogravimetric Analysis (TGA) is a thermal analysis technique that measures changes in a material's mass as a function of temperature or time under a controlled atmosphere.

It is widely used to characterize material composition, thermal stability, and decomposition behavior.

Get Expert Analysis of Your Material

What is Thermogravimetric Analysis (TGA)?

TGA provides critical insight into a material's thermal behavior and composition in a single test. It allows for identification of moisture content, volatiles, organic vs. inorganic content, and thermal degradation points.

This technique delivers high-resolution, quantitative data ideal for material screening, formulation studies, quality control, and material analysis.

Our Process

Sample Preparation

Solid or semi-solid sample (10–50 mg) is prepped and conditioned.

Load into TGA

Sample is placed on a microbalance inside a temperature-controlled furnace.

Heat & Measure

Under inert or reactive gas, the sample is heated while mass changes are recorded.

Analyze Results

Mass-loss data is used to assess thermal stability, composition, and decomposition.

TGA Instrument Used

TA Instruments TGA 5500

- Mass Sensitivity: 0.1 ug

- Temperature Range: ambient to 1200 °C

- Calorimetric Accuracy: ± 2% (based on metal standards)

- Controlled Heating Rate (up to 1000 °C): 0.1 to 500 °C / min

- Nitrogen Atmosphere

Strengths

- Exquisitely precise weight sensitivity – can detect sample mass changes < 0.1 ug

- Only a few milligrams of material is needed due to high instrument sensitivity

- Minimal sample prep

Limitations

- Not available for measurements with temperatures below ~ 25 °C

Your Material Analysis Begins Here

Our team of experts is ready to provide a detailed and accurate quote tailored to your specific project requirements

Sample requirements

- Solids, powders, and semisolids accepted

- Minimum Sample Mass: ~ 0.5 g

- Sample material must have no chemical incompatibility with pan material; pan options:

- Platinum (Standard and High Temperature options available)

- Ceramic

- Alternative pan types can be procured if needed

- Powders preferred; non-powders must be able to be trimmed to fit TGA pan

- Safety datasheets of sample materials are required