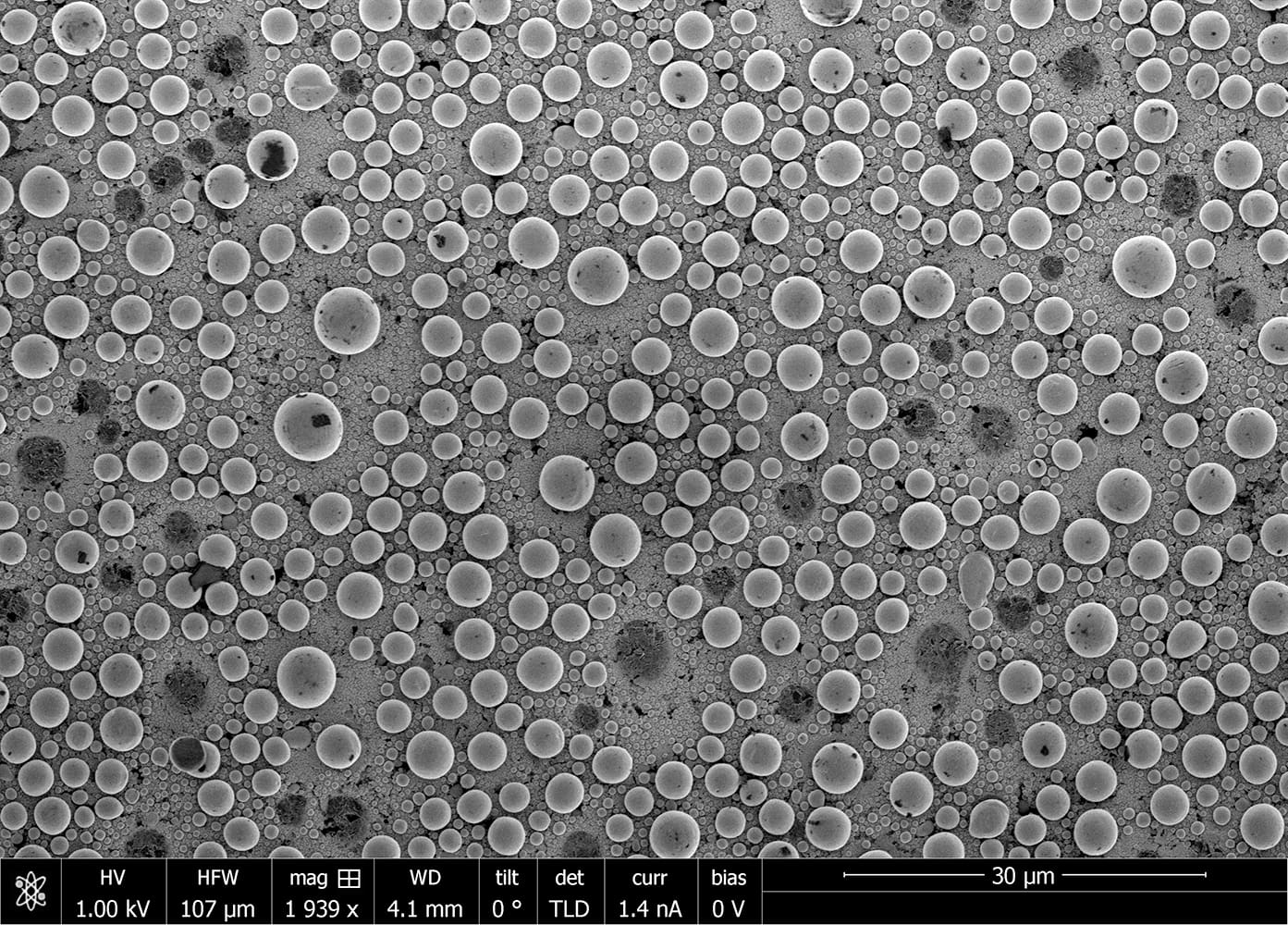

Scanning Electron Microscopy Analysis (SEM)

SEM analysis can produce images with resolutions below 1 nanometer (nm), and large depths of field to highlight surface topography and sample morphology.

A Scanning Electron Microscope (SEM) scans the surface of solid samples living and nonliving by rastering a high-energy electron beam. Because of the high accelerating voltage used to power the electron beam, SEMs yield resolution limits orders-of-magnitude improved over conventional light-based microscopes.

Get Expert Analysis of Your Material

What is Scanning Electron Microscopy (SEM)?

When performing Scanning Electron Microscopy Analysis, a high-energy electron beam is projected onto the surface of a solid sample (composed of conductive materials such as metals or composites), ejecting electrons, X-rays and photons used to produce high-resolution images and other details information about the specimen.

Capable of achieving a magnification range as high as 100,000x. SEM analysis offers remarkable insights into a material's chemistry and structure, combining both morphology and elemental composition data. Insights from SEM Analysis are paramount to advanced materials research across industries ranging from aerospace to personal electronics.

Our Process

Sample Preparation

Mount samples on SEM stubs. Apply a conductive coating (e.g., gold or platinum) to non-conductive materials to reduce charging.

SEM imaging

Scan the sample with a focused electron beam in vacuum. Collect SE for surface detail, BSE for compositional contrast, and EDS for elemental data.

Multi-Modal Acquisition

Capture images using multiple modes (SE, BSE, EDS). Optional enhancements include CL for luminescence and in-lens SE for finer resolution.

Analysis & Reporting

Interpret structural and elemental features. Deliver a report with imaging parameters, annotated images, and key findings.

ThermoFisher Scientific Helios 5 UC (x3)

A specific model of an SEM manufactured by Thermo Fisher Scientific, the ThermoFisher Scientific Helios 5 UC (x3), incorporates DualBeam technology, advanced electron optics, and high current abilities using a Gallium (GA) source.

- Maximum Horizontal Field Width: 2.3 mm at 4 mm WD

- Electron Beam:

- Resolution Limit: 0.7 nm at 1 kV

- Current Range: 0.8 pA to 100 nA

- Accelerating Voltage Range: 350 V to 30 kV

- Ion Beam

- Resolution Limit: 4.0 nm at 30 kV using preferred statistical method

- Current Range: 1 pA to 100 nA

- Accelerating Voltage Range: 500 V to 30k

Strengths

- High-resolution imaging

- Precise compositional analysis

- Versatility among various scientific industries

- Non-destructive analysis (allows repeated analysis of the same sample)

- Provides topographical and crystallographic information about material structure

- Indispensable aid in gaining an in-depth understanding of material properties

Limitations

- Cannot deliver information about the internal structure of samples

- Operating in a vacuum chamber hinders the analysis of gases or liquids

- May introduce image distortions due to charging effects on non-conductive samples

Ready to unlock detailed insights into your materials?

Sample Requirements

Solid phase

Conductive samples yield best results; insulating materials must be coated

Maximum lateral dimension: 150 mm

Larger samples (up to 300 mm) can be accommodated through a network partner; please contact us for more details

Maximum vertical height: 55mm

Maximum sample mass: 500 g

Vacuum stable

Get high-resolution imaging and elemental analysis tailored to your application

Our SEM services deliver precise data and expert interpretation to accelerate your materials development.